Concrete Finishing

Updated: 2021-10-23

Article by Bill Bradley

As soon as possible after the concrete has been placed and screeded level, the preliminary float should be started. The idea is to even out the rises left by the screeds. Just doing this will also bring to the surface an amount of cement and fines slurry that will form the eventual top layer.

Bull float and Edging

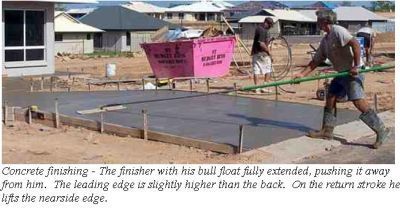

As soon as the concrete in a fairly large section has been put down and screeded the surface is worked with a float and edger. These three guys in the photograph emptied and spread a full 7cuM. truck load, before starting with the floating, but if it was a larger job, more men would be needed and one or two guys would drop back and start finishing, while others carried on with the pouring. The timing is critical, leave the finishing late and it will be so much harder or even impossible.

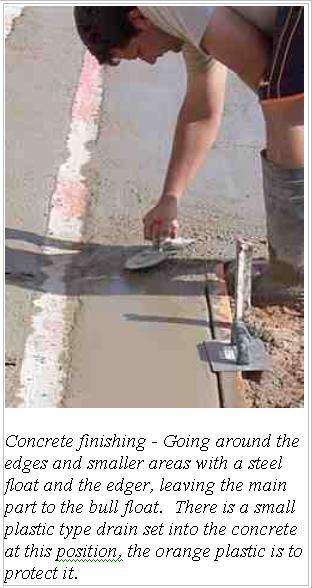

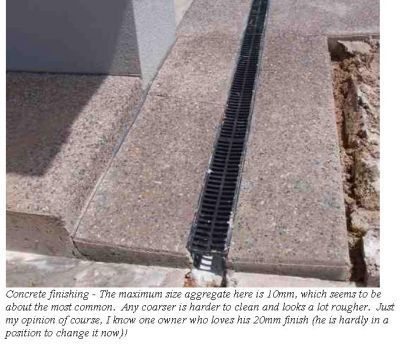

Concrete finishing - Going around the edges and smaller areas with a steel float and the edger, leaving the main part to the bull float. There is a small plastic type drain set into the concrete at this position, the orange plastic is to protect it.

- The floating levels out the screed marks. It pushes down slightly the larger pieces of aggregate and brings to the surface a small layer of fines that the finish consists of.

- Where possible the bull float is used in length ways and then sideways across the slab, to even out discrepancies.

- On a small paving job it is quite easy to do this stage with a hand held wooden float about 300 long. Sometimes off a plank that is stretched over the concrete.

- The bull float does this job a lot easier of course. It has a small pivoted connection from the handle to the blade, so that when the handle is twisted the blade lifts up either at The front of the back.

- The floating goes completely over the control joints. They have a small 3mm or so strip that gets pulled off when the concrete is hard enough to walk on, leaving a nice sharp looking edge.

- While the floating is going on another guy goes around the edges with an edging tool that forms a curved edge.

- When the floating is happening the surface of the concrete will take on a moist shine. If the concrete was fairly wet to start with, then it is quite possible that bleed water will rise to the surface.

- You must try to get rid of this water, either by sponging off or sometimes it is possible to stretch a garden hose across from side to side and slowly drape the excess water to one side with it.

That is it for the first and hardest part of the job. The initial floating is finished. The pros clean their tools, and sit down and have a rest for a couple of hours or so. The next stage is the final finish, and whatever finish it is going to be, it does not start until the watery shine has gone off the face of the concrete and touching it only leaves a small indentation.

I can't give any particular time to wait, because conditions vary. For instance, with the job illustrated the main driveway is in the sun, that will "go off" quicker than the footpath in the shade. If a breeze is blowing, same thing, faster drying.

- A lot of amateur concrete pours don't get past this stage, after a hard strenuous job the volunteer labour is ready for a few beers and they get stuck into it.

- Again, if you have the concrete in flat and level, resist the temptation to play about with it. You won't improve it any by working over it with a steel float if it is not ready.

When the concrete is ready to do the final finish you have a few options.

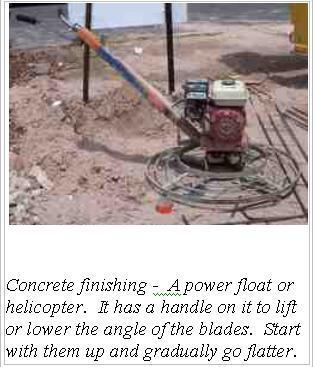

- Work over it with a steel float to give a harder, smoother and denser finish.

- Using a steel float, and this applies to power floats (helicopters) as well, when the surface is wetter you work in broad sweeps with the leading edge of the float lifted a few mm.

- As the concrete gets harder you go over it again with the float almost flat to give it the final finish.

- That could be it, done. Or from that you could go on to give the surface a broom or a sponge finish.

- Broom or sponge is done to walkways and footpaths, and is seen as easy and rough finish, but the point is, for it to look good, the surface should be good before the broom or sponge is used.

- Sure a broom or sponge can cover up small imperfections, but that's it. Get it right with the steel float first.

The driveway job that I have pictured was done with an exposed aggregate finish.

- When the surface was only just hard enough to walk on the guys sprayed the surface with a retarder solution.

- I have used commercial retardants in the past to do the job, but someone has worked out that sugar works just as well. Two kilos of sugar mixed in a garden type spray does the job.

- Shortly after, they work over the surface with a 3000psi pressure cleaner, keeping the fan wide and well away from the surface.

- At the same time a guy will be using a stiff bristle broom to also work over the surface.

Comments (0)