Wood fiber laminate wall panels expand the possibilities for wall finishes. Although laminate panels are not very popular for residential interior finishes, they can be used as wall coverings in less frequently used rooms. We used laminate wall panels to finish the sauna’s relaxation area and attic rooms, which allowed us to share personal feedback on them and their installation.

Laminate Panels

There are several types of laminate wall planks, some of which are also manufactured in Lithuania. The most popular are Polish laminate planks, with slightly better quality German laminate planks. Laminated planks consist of a 6-10 cm wood fiber base layer. The density of the wood fiber can vary, which can affect the product's price and durability. A design is applied on top of the wood fiber, followed by a laminate layer. The laminate layer is much less durable than flooring laminate and is often thinner.

The price of laminate panels is quite disproportionate to the product's properties. Compared to laminate flooring, the base wood fiber is softer, the laminate layer is easily scratched, and there is a limited selection of designs. At the same time, the price of laminated wall panels is similar to mid-range laminate flooring. However, it is possible to buy laminate flooring at a lower price during sales.

Sonoma oak laminate wall panels finish.

The advantage of using laminate for wall finishing comes from the ease and speed of installation. Laminate wall panels are significantly wider, with the most popular being about 30+ centimeters. The large width is likely due to the lower density of the fiberboard and its direction, which is less prone to shifting than higher-density fiberboard used for flooring. Additionally, the lower-density fiberboard is less likely to warp the panels as they expand.

Installing laminate panels is simple and does not require special qualifications. Another significant advantage is the ability to create seamless corners. Laminate panels can be bent to form a corner without a joint. The work speed is also incredibly high – after installing three panels, you’ve already covered a meter of the wall with complete finishing.

Laminate Wall Panel Installation

The laminate packages should be brought into the room where they will be installed at least one day in advance. The typical room temperature and humidity should be maintained.

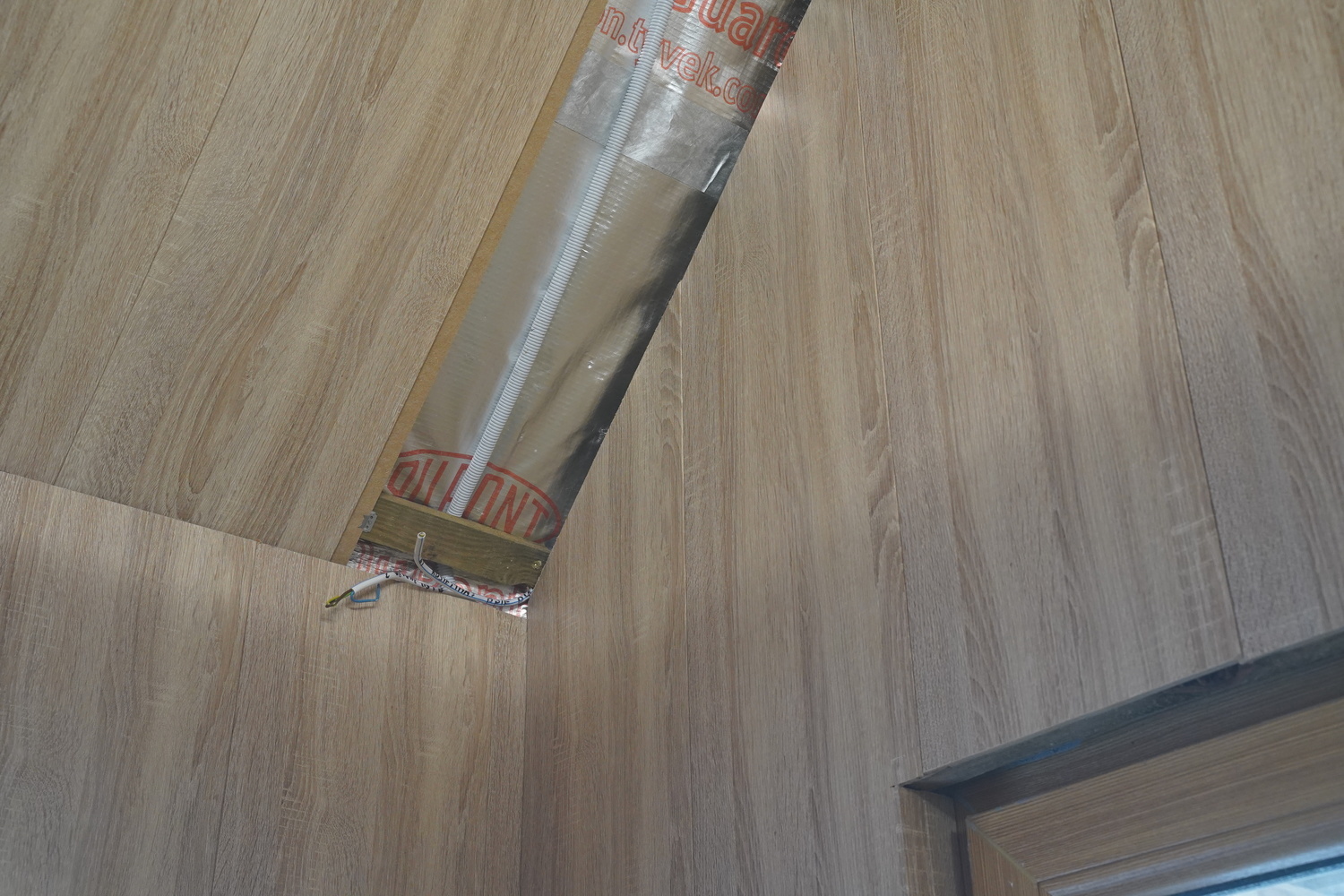

Laminate wall panels are most commonly installed on a frame wall. Battens are fixed onto a vapor barrier film, ensuring a ventilated gap between the laminate panels and the film. The most commonly used battens are 25x50 mm in diameter, spaced 40-60 cm apart. The spacing between the battens depends on the thickness of the laminate panels and the intensity of their use. The laminate panel will hold well even with 80 cm spacing between the battens, but such a large gap can create a risk of bending, even when leaning against it.

Laminate wall panels are most commonly installed on a frame wall. Battens are fixed onto a vapor barrier film, ensuring a ventilated gap between the laminate panels and the film. The most commonly used battens are 25x50 mm in diameter, spaced 40-60 cm apart. The spacing between the battens depends on the thickness of the laminate panels and the intensity of their use. The laminate panel will hold well even with 80 cm spacing between the battens, but such a large gap can create a risk of bending, even when leaning against it.

Installing laminate panels on walls is best after the flooring is completed. It is recommended to leave a gap of about 10 mm at the bottom. Electrical wiring should also be routed, and the locations for outlets and switches should be marked.

Laminate Wall Panel Fastening

Laminate wall panels can be either glued or fastened with staples. Both methods can be used simultaneously. Panels fastened with staples will stay firmly in place but may allow movement, which is important in spaces with significant temperature and humidity fluctuations. When glued, a more reliable and impact-resistant structure can be achieved.

The laminate wall panels are attached to the battens. Mark the distance, apply the glue, secure the laminate panel, and fasten it with staples. The panels can be fixed using pneumatic staples or nails.

Laminate panels can be glued onto boards or concrete. In our case, laminate panels were used to cover a concrete chimney. The result was very attractive, especially due to the seamless bending.

For panel installation, Soudal Bond Easy panel adhesive was used. The adhesive is applied so that when pressed, it covers about 40% of the surface. Before applying the adhesive, a light spray of water is applied. After spraying the adhesive, wait for about 1-3 minutes before pressing it into place. It is also recommended to apply additional pressure to the laminate panel.

Electrical Installation in Laminate Wall Panels

Electrical installation boxes are mounted similarly to drywall. One panel will be too weak to support an electrical outlet. It is recommended to reinforce the panel in the area where the electrical box will be by adding an extra panel. The same wall panel can be used, which can be glued to the reverse side. Once the panel is attached, it can be drilled with a wood drill bit.

The electrical installation box is recessed into the laminate panel. The edges are trimmed with a sharp knife. On the other side, the installation box is secured with special wings.

Bending Laminate Panels

Bending laminate wall panels requires a bit more skill. The goal of bending is to create smooth corners without joints or seams. If you cut too much, the laminate will be cut through. If you don't cut enough, the wood particle board will break along with the laminate. The cutting should be done with millimeter precision so that only a small amount of the laminate is visible.

To cut laminate, you will need a tapered router bit. The bit should be slightly larger so that the cut goes through the entire thickness of the laminated panel.

The router is pushed along the guide rail. The guide rail is more convenient because the rubber on the bottom presses down, ensuring the router stays firmly in place.

It's better to apply glue at the bending point. The glued corner becomes monolithic and significantly more resistant to damage.

Cabinet Mounting on Laminate Panels

It will not be possible to mount heavy cabinets directly on laminate panels. You will need to prepare the areas where the cabinets are expected to be placed. Cabinets can be attached by screwing directly into the battens. To do this, you need to mark the locations of the battens. Additionally, in the areas where the attachments are expected, you can glue a second panel to thicken the laminate. Fastening can be done using drywall anchors.