Laminate flooring is a popular and cost-effective choice for covering floors. It is easy to install, durable, and suitable for underfloor heating. With minimal subfloor preparation required and high wear resistance, laminate floors can last for decades. Plus, they offer a simple DIY-friendly installation, making them a great option for updating any space.

Best Laminate Flooring

Since there is a wide variety of laminate flooring, choosing can be challenging. Laminate flooring can generally be classified into economy, mid-range, and premium categories. Each of these categories has its characteristics and demand. Probably the biggest challenge in choosing is to distinguish between when a seller is trying to sell a lower-end laminate at a higher price or when the price of laminate flooring is excessively inflated. Once you understand the criteria for choosing laminate, buying higher-quality flooring for a lower price is possible. Due to intense competition, discounts sometimes occur.

The best laminate floorboards are resistant to environmental factors, and moisture and can be installed very easily.

To choose the right laminate floorboards, it’s important to understand the factors that contribute to their price. A significant portion of the laminate floorboard price is determined by the base. The base is usually made from compressed wood fibre or particle boards. A high-quality base can, with some exceptions, be recognised by its weight. A heavier board indicates a higher board density. Higher density greatly affects sound insulation, moisture resistance, and durability. Density is measured in kg/m³, with lower-density MDF being less than 850 kg/m³ and higher-density HDF/HPL being 850+ kg/m³. The strength of the base often influences the reliability of the locking/joint mechanism as well. This is why economy-class laminates often require an entire row of floorboards to be assembled. The bottom of the base often has an additional stabilizing layer made of HPL, plastic, or other durable and flexible materials. The base significantly impacts sound insulation.

Video about laminate flooring installation on Youtube: Laminate floor installation

The video explains the process of laminate floor installation while demonstrating the key moments of the process. It discusses the choice and installation of the underlayment, explains the selection and setup of the laminate floorboards, and highlights what tools are needed for the process.

Laminate Resistance Classes

A picture is placed on the base, and it is laminated. The laminated surface protects the board from wear. The quality of the laminate affects its resistance to abrasion. Several indicators determine the characteristics of the laminate. Most often, the laminate’s wear resistance class is indicated on the boxes. The higher the number, the more resistant the laminate flooring is to environmental impact. In the past, class 21, 22, and 23 laminates were used for residential spaces. Nowadays, these are difficult to find, with the lowest class in most stores being 31.

Class 31 laminate is recommended in rarely used premises such as bedrooms.

Class 32 laminate is used in areas with moderately used areas, such as bedrooms or less frequently used living rooms in vacation homes.

Class 33laminate is designed for frequently used premises, such as living rooms.

Class 34 laminate is intended for highly used areas and commercial spaces.

When purchasing a larger quantity of laminate, it is wise to check the labels and also to request documents and certificates.

Resistance Classes may be written on the box, but they may not be confirmed by independent certification centre tests. It is important to critically assess very cheap laminate flooring that claims, for example, a 33-wear resistance class. The same caution should be applied when seeing labels like AQUA or WATER RESIST on low-cost laminate. Another important characteristic is abrasion resistance.Laminate floorboards are classified into AC1, AC2, AC3, AC4, AC5, and AC6 classes. A higher class indicates that the laminate will be more resistant to wear.

Manufacturers often introduce additional technologies that increase resistance to wear and abrasion, such as aluminium oxide. However, the exact amount of aluminium oxide is rarely specified, making it unclear how much better the laminate’s resistance will be as a result.From experience, it can be summarized that in large construction retail centres, economy-class laminate is often sold at the price of mid-range laminate. Design stores typically offer mid-range and premium laminate at prices comparable to high-tech laminate. Large specialized flooring stores often sell mid-range and premium classes at reasonable prices.

Laminate Flooring Design

The top layer of laminate consists of a pattern and laminate itself. This can be a single layer glued onto the base. There are many different laminate patterns, with the most popular ones imitating wood and stone surfaces. Laminate colours may change over time. Cheap laminates are often not UV resistant and lose their original colour.

The surface of embossed laminate floorboards can have a texture replicating the pattern.

The joining of laminate floorboards can reveal its class based on price.

The cheapest laminated floorboards connect without grooves, which is impractical. As the conditions change, a permanent gap may appear between them.

More expensive floorboards usually have a larger or smaller groove. Laminate floorboards with a deeper groove resemble solid wood boards, while a smaller groove resembles parquet flooring.

Preparation for Laminate Installation

Laminate flooring is installed on a smooth surface, so, most likely, preparing the floor surface will take more time than the installation itself. The floor surface can be levelled in several ways. A concrete surface can be smoothed using self-leveling compounds. Floors can also be levelled using panels. Gypsum boards for flooring are becoming increasingly popular. The panels are laid in two layers and joined together, to achieve a smooth and sturdy base.

The top row of drywall panels is installed perpendicular to the bottom row. Such a drywall base is suitable for installing electric heating.

Laminate Flooring Underlay

An underlay is placed beneath laminate flooring. Various types of underlays are used for that.

The thickness of the underlay is chosen based on the floor's level. In most cases, if the subfloor is well-prepared, a 3mm underlay will be sufficient. The cheapest option is an expanded polyethene underlay, while cork underlays are more expensive and offer superior properties.

The underlayment is placed on a thoroughly cleaned surface and is taped together. Packing tape can be used.

Installing Laminate Flooring

Laminate flooring boxes should be brought into the room where they will be installed at least two days in advance. This allows the laminate to acclimatise to the room's temperature and humidity.

It is advisable to inspect the floorboards and arrange the pattern after unpacking. Floorboards from different packages may have slight variations in shade, which is quite common. It is often preferred to lay the laminate flooring in a way that prevents the pattern from repeating on adjacent boards.

Laminate floorboards are laid from the corner, moving from left to right. Cheap laminate floorboards may still be connected along their entire length, but most modern ones are installed individually. It is important to ensure that the last floorboard in the first row is not shorter than 40 centimetres.

The laminate floorboard is positioned at approximately a 45-degree angle. Typically, the gap between them is a few millimetres, but it depends on the specific locking mechanism. The distance between the joints of adjacent boards should be no less than 15 centimetres; however, the manufacturer usually specifies the allowable gaps.

Gaps should be left between laminate floorboards and the wall. The required gap is specified by the specific manufacturer. Typically, this is around 10mm.

The floorboard fully slides into place after additional tapping. It is best to tap it in the middle first, then in the farthest corner near the locking mechanism and, finally, along the joint. The floorboard will sit completely flush after these steps.

A piece of the same laminate board can be used for tapping. There are also special tapping boards designed for laminate installation and these are better to use when installing laminate with lower density.

The laminate board is tapped from the side, fully engaging the locking mechanism.

The edge board is inserted from the side using a tapping tool. Some floorboards may require the edge to be pressed down, as shown in this photo.

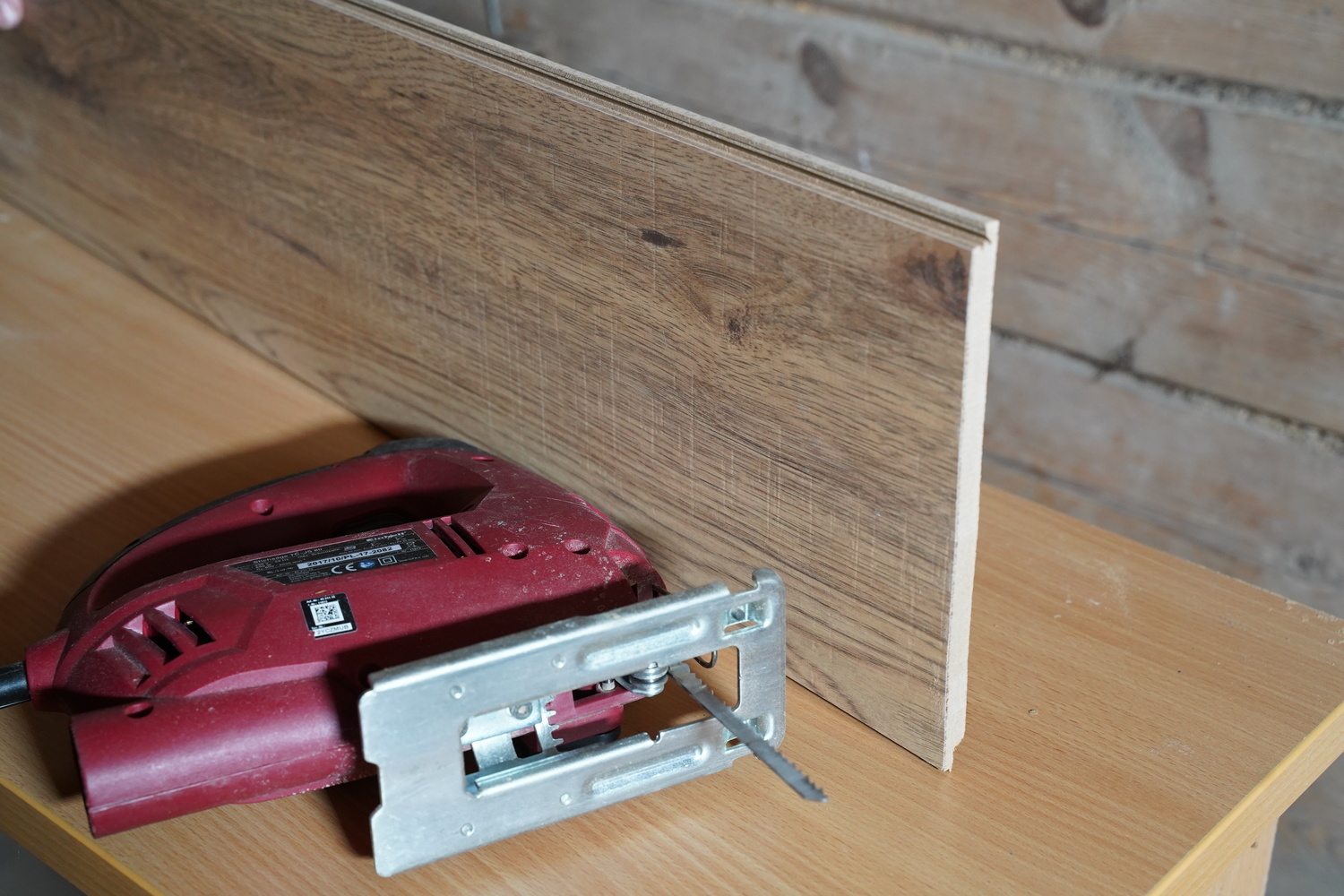

Cutting the Laminate Floorboards

Laminate floorboards are very easy to cut using a fine-toothed saw. The cutting side depends on the saw blade. Often, when cutting, one side of the cut may splinter. To determine which side splinters, make a test cut. The side that splinters is the one toward which the saw teeth are directed.

A saw with downward-pointing teeth tears the opposite side. In this case, draw the cutting line on the good side of the laminate floorboard.

Cutting line.

It is not difficult to make holes into the laminate for it to fit around radiator pipes. They can be made using a spade drill. If the pipe is further from the wall, a hole is drilled, and then the cut is connected using a fine-toothed saw. The remaining piece is placed by adding the floorboard and can be glued to the sides of it.

Laminate for Underfloor Heating

Laminate floorboards are perfectly suitable for underfloor heating. This can include water-heated floors, as well as floors heated by electricity or infrared rays. The best option is laminated flooring with higher density.

Laminate flooring can be installed over infrared heating film. The film is placed on a special underlay then a stabilized polyethene film is laid over it.

Video explaining the laminate flooring installation over the underfloor heating: Laminate floor installation

The video briefly explains the installation of laminate flooring over underfloor heating, including the steps and materials involved.