Window installation in a timber frame house is a job that requires thoroughness. Everyone seems to already know how to correctly install windows. However, you can spot small mistakes in pretty much every object, which the construction workers may deem insignificant, but they become very obvious as soon as you actually start living in it. I installed my windows myself in order to make sure everything is done correctly. Mistakes are often made probably because a perfect window installation takes a lot of time, especially because of technological intervals.

Window opening installation and insulation

In a timber frame house, the window opening is constructed from the same wood as the whole timber frame. The window is affected by the weight of the roof. The wider the window, the more intricate solution is needed for the window frame to withstand the load.

Window opening installation scheme. A plank is placed vertically on the struts that would be above the window. It cannot be bent. It is placed closer to the outside because warmer air moves towards colder air.

The constructions are insulated from the outside with a wool layer of at least 50 mm.

The sealing of the construction around the window

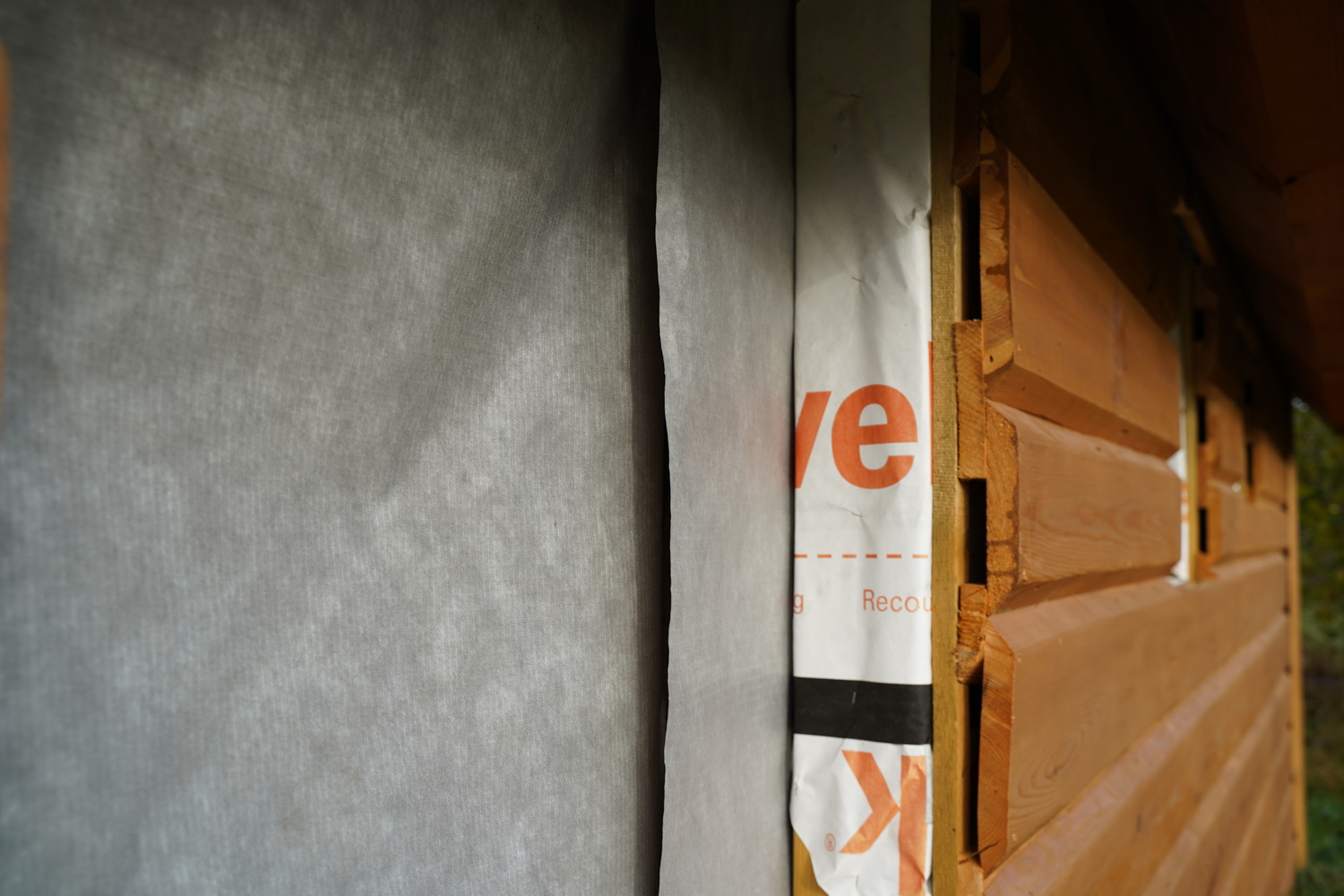

The heat insulation plates lose their insulating abilities if not properly insulated. They are insulated by wind from the outside and by vapour from the inside. Various wind-resistant plates can be used on the outside. Because of their low vapour conductivity, the OSB are not recommended. It is more preferable to use facade plasterboards or fibre cement boards. Heavilly pressed stone wool boards can provide additional heat insulation.

The house wrap is cut and fixated on the window opening borders.

The vapour barrier membrane is fixated from the inside.

The vapour barrier membrane is cut and fixated on the opening. The facade house wrap and the inside vapour barrier membrane are thoroughly glued together so there are no empty spaces.

The vapour insulating mastic that I used and that, in my opinion, is best for this job, is Soudatight Hybrid. It is easily spread, glues well and fills the spots that are harder to access. When dried out, it becomes a capable film that is also UV-resistant.

The facade decoration is applied.

Putting the window in

The window needs to be in the insulating layer. The window is usually put closer to the inside. The optimal distance can be calculated by the builder by taking into the account the width of the insulating layer.

The window is shored from every side with the use of shims. While shoring, it is absolutely worth it to fixate the window to the top. However, before spraying the foam, the top shorings are removed. After shoring, fixating and aligning the window, it is screwed from the side with wooden screws. Special fixating frames can be used.

The window is usually made with a few degrees lean to the inside. After perfect alignment, the connecting rod usually tends to close. So, after shoring, you should open the connecting rod and find a position where it is not moving.

There are multiple ways of shoring. Either wood or plastic shims can be used. Pay attention to the connection between the house wrap and the vapour insulation mastic. You should use reliable tapes for gluing.

Window sealing

Usually, the most mistakes are made when sealing the window. The workers may want to finish the job as soon as possible, and so they would spray the foam and put the sealing tapes too early. Or they wouldn’t use sealing tapes at all. Polyurethane foam is not resistant to impact from the outside. It is quickly deteriorated by ultraviolet rays and loses its abilities when affected by humidity. It needs to be protected from outside impact. Correct foam must be used.

For a wooden frame that changes its measurements based on the humidity and temperature regime, elastic foam works best.

I have tried out and can easily recommend Soudal FlexiFoam. It stays elastic for many years even after moving in sync with the surfaces. This foam possesses a great heat and sound insulating ability. In my opinion, it’s the ideal sealing foam for windows. Sprayed bottom to top. Just make sure to use brand pistols, as using cheap ones can often lead to problems.

Window foam sealant is used in a temperature of >0 °C. However, it is best to seal windows in a temperature of > +10 °C.

The foam can be smoothed out after a couple of hours but I usually leave it until another day. The foam that is sticking out should be cut off instead of pressed in, a mistake some workers make. Foam that is pressed in won’t be fully proficient in insulating heat.

Before spraying, the surfaces have to be humidified. This is a must for the foam to dry.

For even air bubbles to form in the foam structure, humidity is needed. Without humidifying, the air bubbles might become very big, which would mean that the heat insulating abilities weren’t as good.

Window foam sealant has to be isolated from both the outside and the inside against the outside effects. Sealing tapes and thickening mastic are used for this purpose.

When mastic became available, I switched to it. It is more reliable, simpler, faster, and very similar in price. I had to dismount the window with tape sealing. Unfortunately, the tape usually unglues in some places, as it hardly sticks to the timber. Or perhaps it unglues because the timber is moving. So, glue and staple fixating should be used in addition with the tape. Mastic Soudatight Hybrid glues to the surface very well. It stays elastic and changes its parameters in sync with the window’s and window opening’s surfaces. It also sticks to the window foam sealant. The mastic is spread by a hard-bristle brush and used in a temperature of >0 °C. It can be warmed up to the room temperature so that it becomes more fluid.

After spreading the mastic, it is important to immediately take the protective tapes off (the yellow paint protective tape or the factorial window protection tape). Then, an even mastic line forms.

The biggest enemy of a house is mice. Seal all holes with a small-holed mesh.

Timber frame house window decoration

The window opening sides are decorated with the same materials as the facade.

Wood panelling window decoration.

Frequently asked questions about window installation in a frame construction:

What height above the floor should the windows be installed?

The windows can be installed just above the floor. The most common height, however is 60-90 cm.

Can the foam be cut?

Yes, the foam can and needs to be cut if it sticks out and interferes with further installation works. Just remember to seal it afterwards.

Can the window frame be drilled?

Yes, the window frame should be drilled when fixating the window to the opening. Nail plates can be used.

What should be the distance between the window opening and the window frame?

The optimal distance between the opening and the frame is 25-30 mm. However, it can be up to 50 mm.

Before putting the window in, do you need to wait for the frame construction to “settle”?

When building a house from dried and calibrated timber, the parameter variations are minimal. The windows are put in after putting on the roof - the part that gives the construction the most weight. Although, the construction process might vary a bit more with the use of naturally dried timber. However, by the time you have installed the roof, the construction should be stable.

Why does the area around the frame become misty after installing the window?

There can be a few reasons. If the windows are installed in an older house with no ventilation, the increased sealing increases the humidity in the premises, and the vapour condensation takes place on lower-temperature surfaces.

If there is ventilation, however, there might be problems with the window installation. A common one is window foam sealant that has stuck off. This might be because of its low quality, if you opted for a cheaper one. Some foam has the ability for a secondary dimension change, where they shrink after completely drying out, leaving empty spaces. If the window installation was rushed and the sealing tape was hidden before the foam layer had time to fully form, you would have a hidden empty space and a heat bridge. Misting can also happen because of a humidity surplus created by the drying of the building materials.