On your own terrace, you can do more than just have breakfast or enjoy the evening. It’s a perfect place to relax when you want to escape the summer heat inside the house.

How to Choose a Location for the Terrace Construction

The construction of the terrace depends on what kind of terrace you want, its size, the materials used, whether it will be fully open or partially enclosed. So, the first step is to decide on the appearance and design of the terrace.

If the terrace is included in the house design, its foundation can be built when constructing the house foundation. However, if the idea of a terrace comes later, after the house is already built, that's not a problem either. Once you’ve lived in the house for a while, it becomes much easier to decide the best location for the terrace. When choosing the location for the terrace, it’s very important to know the position of the sun at specific times of the year and day—whether the terrace will primarily receive morning, midday, or evening sun.

If you enjoy sitting outside while the sun sets, the terrace doesn’t necessarily have to be on the western side. If the house is surrounded by forest, the most beautiful reflections in the summer are on the eastern or southeastern side, on the treetops. Only later does the sky turn red in the west. In winter, reflections are found in the east or even the northern part of the house, as the sun sets nearly in the south. Pay attention to your surroundings, and you’ll understand where the most pleasant spot for spending leisure time is. The best location is one that shields the terrace from northern winds and opens to the east, west, or south.

Another important consideration when building a terrace is making sure it’s easy to access. Therefore, it’s better to have it near the living room or kitchen. It’s very convenient if there’s a window or door from the kitchen that leads to the terrace—this way, it will be easy to walk out and serve snacks to family members sitting on the terrace.

Protection from wind and prying eyes is also an important factor. If there are children in the house, their safety should also be taken into account. The terrace can be at an angle to the house or partially covered by a roof. Terraces built on elevated pile foundations are more common when the house’s foundation is high or when the house is on a slope.

Once you’ve decided on the terrace’s location, you must also determine its size. A terrace is similar to a kitchen or living room, but outdoors, so its size depends on the family’s needs. I believe that for a family of 5-6 people, an optimal terrace size would be 14-25 square meters, though those who can allocate around 40 square meters for a terrace will definitely be happy.

You can save on materials if you make the terrace rectangular, as this way, you’ll avoid waste from leftover planks.

Materials for Outdoor Terrace Construction

There are many different materials you can choose for the flooring of your terrace. Recently, wood and plastic composite decking has become increasingly popular. You can also use thermally modified wood (thermal wood) or impregnated solid wood planks. Thermally modified wood withstands environmental conditions fairly well, but it is quite brittle. Solid wood decking is not ideal for building a long-lasting terrace; such a terrace will require regular maintenance and updating. The situation is a bit better with larch wood planks, but even these require much more care compared to using wood composite decking.

WPC Decking (Wood Plastic Composite)

WPC decking also has some nuances. The price range for WPC decking is very wide, and there are significant differences in quality. You can find WPC planks for as low as 20 euros per square meter in retail stores. In specialized WPC decking shops, the price for WPC terrace planks typically starts from around 90 euros per square meter. So, what’s the difference between cheap and expensive WPC decking?

Cheap WPC planks are made from recycled materials, including plastic waste and wood production by-products. Expensive WPC planks are made from primary plastic and wood raw materials. When using recycled materials, it’s impossible to maintain consistent quality. Because of this, terrace installers often complain that with cheaper WPC decking, terraces need to be reassembled more frequently because some of the planks crack.

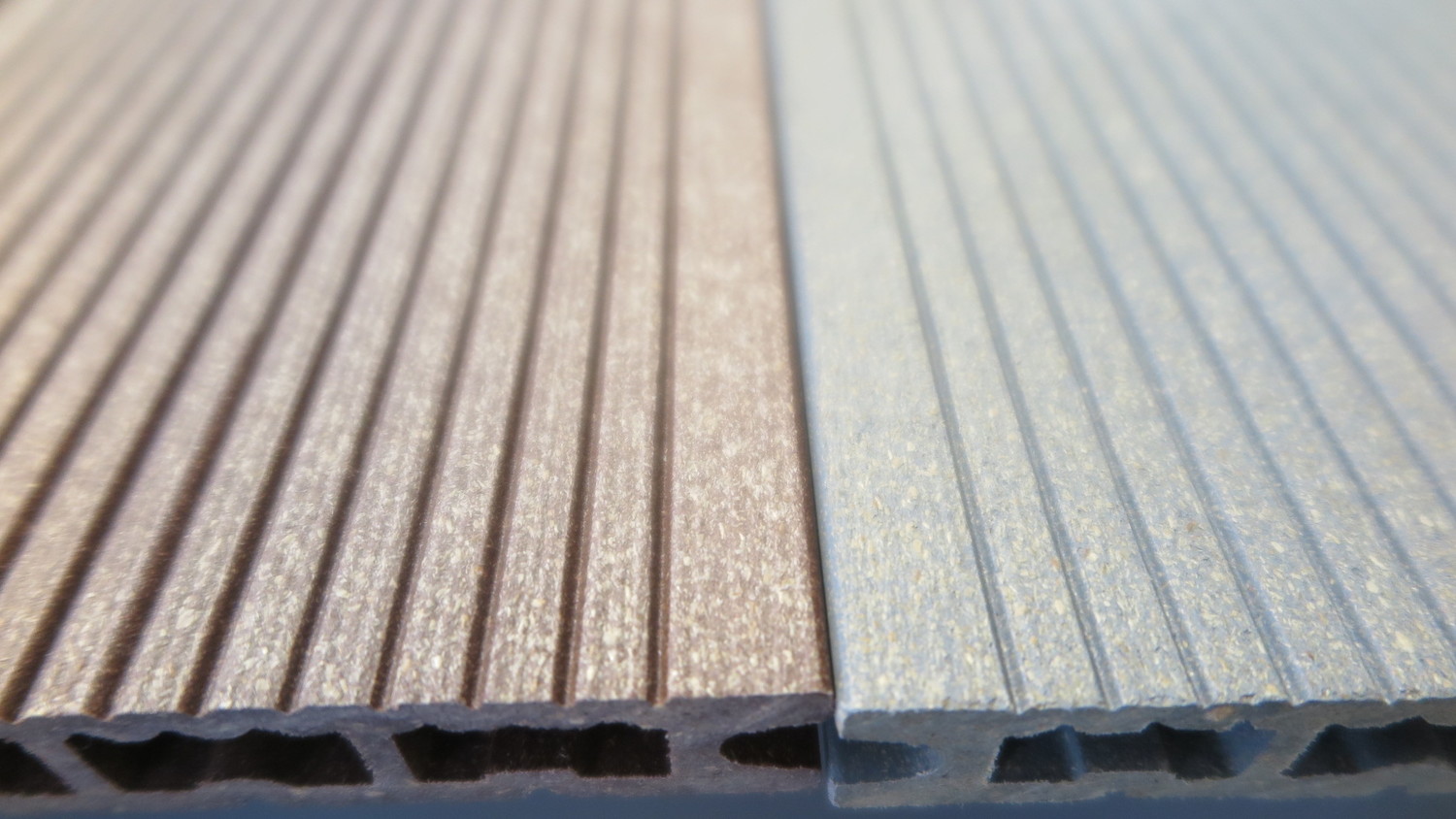

Above: A cheap WPC plank with visible structural damage. This type of plank will have the same issues as a regular solid wood plank—it will crack, split, and be difficult to maintain because it will absorb water and contaminants.

Below: A WPC plank from a Polish manufacturer with a uniform structure. Such planks do not absorb water or pollutants, are easy to clean, and maintain consistent performance for decades.

Cheap Decking Planks

Cheap decking planks are usually available in a few colors and with a classic grooved surface. When building a terrace for your home, you want it to match both the house and the surrounding environment. In specialized WPC decking stores, there is a wide variety of surfaces and colors to choose from. Reputable manufacturers invest not only in the quality of the planks but also in their design and functional properties. Safety is especially important for outdoor terraces. Manufacturers offer smooth-surfaced WPC planks with extremely low slip resistance.

Solid WPC Decking for Construction

For terraces built with solid wood, the wood must be impregnated deeply, as it is constantly exposed to moisture, and drying conditions are often not ideal. When choosing wood, make sure it is not only impregnated but also has the highest impregnation class. The wood used for the terrace frame must have at least class III impregnation.

WPC Insemination Classes Based on Use Conditions

| Class | Environmental Conditions | Protection Against | Products |

| I | Above ground, in dry environments | Insects | Indoor joinery products, intermediate floor details |

| II | Above ground, under a roof, occasional moisture exposure | Insects and fungi | Tile battens, flat roof details, frame house details, parts at risk of condensation |

| III | Above ground, uncovered, outdoors, but not in contact with soil | Fungi | Exterior joinery products, fence crossbars, gates, terraces, playgrounds |

| IV | Contact with soil or fresh water |

Fungi |

Fence posts, roofing details, piles, sleepers |

It's worth having your own wood preservative, as you will need it to treat the ends of cut wood. Additionally, it’s a good idea to treat the impregnated wood intended for the terrace with a paint or clear protective oil. This helps prevent small cracks and delays the onset of decay.

Wooden solid wood joists should not come into contact with the ground or concrete. When placing them on concrete, it’s necessary to lay down roofing felt or another similar waterproofing material beneath them. The ends of the wood should be treated with a highly absorbent wood preservative oil or paint. Another important factor when choosing wood is that the dimensions of the terrace beams should be large enough, the joints should be strong, and all metal parts, including screws and nails, should be rust-resistant—either hot-dip galvanized or made of stainless steel. After laying the terrace with solid wood planks, they will need to be renovated after some time.

Meanwhile, WPC products made from a combination of wood and plastic do not change their physical or aesthetic condition even after several years of intensive use. Wood-plastic composite decking boards are produced by both foreign and Lithuanian companies, and the range available is quite wide.

Wood-plastic composite products are valued for their surface durability, resistance to atmospheric conditions, including UV rays, and, most importantly, their low maintenance requirements. These properties justify and compensate for the higher price of WPC products.

Terrace Construction on Pile Foundations

As with any construction project, the most important part of building a terrace is the foundation. The depth of the foundation holes depends on the location of the terrace.

In Lithuania, the frost line is 1.2 meters, so the holes for the terrace piles should be at least this deep. If the house is built on well-draining gravel, the holes can be dug shallower—around one meter. However, it’s not advisable to take risks.

Another important factor is that the hole diameter should be no less than 13 cm, and ideally 15 cm. Holes are typically made using a soil auger. For deeper holes, an auger extension will be needed. Once the hole is dug, a plastic or paper tube is placed in the hole, and the bottom is compacted.

Concrete is poured into the hole, and a reinforcing bar is inserted. The bar does not need to extend the full length of the foundation, but should be embedded at least 150 mm, depending on the load. The bar should be made of stainless steel, and its diameter depends on the distance to the joist.

Preparation for Concrete Pouring

Work can be sped up by leveling the terrace joists before pouring the concrete. After leveling, it will be enough to place the joist system with the reinforcing bars into the concrete. The bar will not bend or sink deeper into the concrete. Ideal vertical alignment is essential.

Terrace Construction Reinforcing Bar Diameter:

- 10 mm for distances up to 60 mm

- 12 mm for distances between 60-120 mm

- 14 mm for distances between 120-250 mm

Before pouring the concrete, geotextile fabric should be laid down. Geotextile prevents the rise of mole tunnels, grass growth, and the formation of ant hills. It’s worth attaching the geotextile to the piles and the wall. Afterward, a layer of gravel, at least 50 mm thick, should be placed on top.

Terrace Construction on Ground

A terrace can be built on the ground or on a flat roof. Adjustable supports are used for this purpose. When constructing on the ground, the base needs additional preparation. If the soil has low water permeability, the terrace may shift during winter. It’s better to remove 30-40 cm of such soil and replace it with a gravel layer. The gravel should be compacted. On top of the gravel, agro fabric is laid, which allows water to pass through but prevents grass from growing.

Often, paving slabs are also laid, which help distribute the weight of the terrace more evenly across the ground. Adjustable supports are placed on the paving slabs, and the outdoor terrace frame will be mounted on them.

Screw-in Supports for Terrace Construction

For those who are not inclined to handle foundation work, ready-made supports can be used—this makes the job faster and simpler, although the cost of pedestals is higher than concrete and reinforcement. In one day, a single person can drill and pour concrete for up to 10 foundation piles, whereas using pedestals, five times more can be installed in the same time, and the joists can be placed as well.

The supports are adjustable, which solves the height issue. They can be installed on concrete, old asphalt, or old tiles. If the base is uneven, slope correctors are added, and the joists and boards are installed. The supports are anchored to the base with fastening elements; they can also be glued with bitumen or left unfastened. If the base is simply a lawn or soil, dig a 50x50 cm hole to a depth of 20 cm, fill it with fine gravel, place the support, and install the terrace. The fine gravel must be compacted.

Outdoor Terrace Construction Frame Installation

For outdoor terraces, it is best to use a double frame. A double frame structure is much more stable than a single frame, as the load is distributed more evenly.

The best materials for the frame are aluminum, galvanized steel, or WPC joists. The use of thick, "non-decaying" solid wood joists is still common. In an open outdoor terrace, such joists will last for a while. However, problems will quickly arise. First, the wood begins to rot around the fastening elements, causing them to move, and the terrace will start to squeak when walked on. There are even more issues when combined with solid wood decking. Over time, fungi invade the wooden joists. When a rotting wooden deck board is replaced, the fungi from the joists will quickly transfer to the new board, significantly shortening its lifespan.

For a terrace made with aluminum joists, the lower row of joists is placed every 70–80 cm apart, with a 20 cm gap at the edges. The second row of joists is placed 40 cm apart when using hollow WPC decking boards, or every 70 cm if using solid boards. At the edges, the upper joists are spaced closer, about 20 cm apart. However, it is always better to consult a specialist for specific guidance.

Outdoor Terrace Construction Decking Installation

Outdoor terrace boards can be fixed by screwing them directly into the joists or using special fastening elements. The decking holders not only secure the boards but also lift them off the joists. The gap created is important because it allows water to dry quickly. If the board is pressed against the joist, water can remain in the gap for a long time, causing the board to change its properties and shorten its lifespan.

Decking holders are made of strong metal, which firmly holds the boards in place. Terrace boards have special edges into which the holders are inserted. It is important that the edges are reliable and can withstand the heavy loads placed on them.

There are various edge finishing options for terraces. Most often, terrace craftsmen use the same decking boards to finish the edges. Manufacturers offer special trims and fastening solutions. This type of finishing significantly reduces the labor costs of terrace installation.

Terrace Glazing

To extend the time spent outdoors, it's worth glazing the terrace. Terrace glazing is not overly expensive, and the cost of glazing is less than the enjoyment of watching sunsets in a warm, wind-free environment. Furthermore, a glazed terrace offers warmth, additional space, and cleanliness—no more scraping leaves off the floor in the fall. A glazed terrace that is sheltered from rain lasts longer.

There are several options for glazing a terrace. The first option is glass framed in aluminum profiles, known as a framed system. The terrace can be glazed on all sides, from the front, from two or three sides—it’s important that the base is stable, immobile, and solid.

All or part of the frames can be sliding, and they can include hinged or sliding doors. In framed construction, 4-5 mm thick tempered glass is used, which can be clear or tinted. The aluminum profiles can come in various colors, typically painted to match the facade color. If needed, the craftsmen can also install a terrace roof, which can be made of polycarbonate or 8 mm thick clear or tinted glass. Framed glazing is stable, durable, and withstands wind gusts well.

A more modern option for terrace glazing is the frameless system, where the glass panels are placed directly next to each other without vertical frames.

Frameless terrace glazing can come in two types or systems, which differ in how they open. The Vizyon system allows the glass panels to slide in one or two directions within profiles, stack together, and, when rotated 90°, align tightly against the wall. With this system, the terrace can be fully opened—100%—as if the glass panels were never there.

Another frameless glazing system is the SCS-X system. In this system, the glass panels also move along tracks and stack one on top of the other, leaving just the width of a single pane, similar to the way a closed book looks.

Both frameless glazing systems are convenient because they are almost invisible. The absence of frames doesn’t obstruct the view of the surroundings, and at the same time, you can practically open the terrace or balcony completely. Frameless balcony glazing is especially useful in cases where glazing is problematic due to heritage preservation or architectural requirements.